Heat Treatment steel strip

The frontrunner in the market of heat-treated steel. Nastech's products are used in automobile industry.

Manufacturing Range

| Material | Specification(mm) | Mechanical Properties | ||||

|---|---|---|---|---|---|---|

| S35C ~ S80C |

|

|

||||

| SK steel(2M~5M) | ||||||

| SCM steel | ||||||

| SKS steel | ||||||

| 50CrV4 |

Surface finish

| Category | Surface Finish |

|---|---|

| Bright hardened | Condition of Bright Heat Treatment Only |

| Polished finish | Condition of Polishing after Heat Treatment |

| Blue or Yellow | Condition of Bright Heat Treatment Only |

| White polished | Condition of Polishing after Heat Treatment |

Strong points of Nastech heat treatment steel

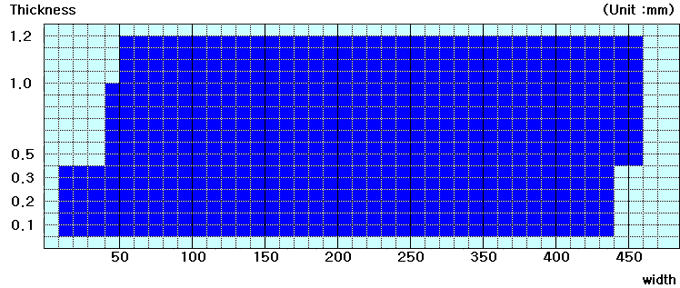

- Diversity of product standards : Shank of all sizes almost in domestic(Thickness 0.3~3.2mm, Width 50~550mm)

- Breakthrough improvement of the flatness : 0.1% × width (1㎛/㎜ width) (0.001 of strip width)

< Existing : QT > < Nastech : Martempering >

- Direct cooling from the high temperature to the low temperature

- Temperature difference between the inside and outside

=> High surface uniformity impossibility 5~8 ㎛/㎜, width

- Cooling after homogenization in directly overhead of Ms

- Leveling during the cooling (After this, passing the Leveling fireplace(爐))

=> High surface uniformity 1~1.5 ㎛/㎜, width

[ SK-5 Standard ] - Direct cooling from the high temperature to the low temperature

- Unpolished Bright Finish Production

Existing Nastech - After Quenching

- Surface uniformity correction in the air - Cooling in the air after Tempering

- After Quenching

- Leveling in the mood of reduction (Leveling Furnace possession) - Cooling during the mood of Gas after Tempering

- Oxidative scale creation on the surface

- Bright Finish on the surface

- Surface polishing before use

- polishing unnecessary

=> Polishing cost reduction is possible

=> Block of the concerns for the thickness variation raising due to the polishing - After Quenching

- Uniformity quality : T/S - Max ±30 N/㎟

Micro structure : Tempered martensite=> Quality improvement, cost reduction

Manufacturing

| Heat treatment method | Internal organization | Tensile Strength | Use | Remarks |

|---|---|---|---|---|

| Martempering | Martensite | 1,500 ~ 2,000 N/㎟ |

|

|

| Austempering | Bainite | 1,350 N/㎟ |

|

|

| Patenting | Sorbite | Condition of material re-rolling 1,200 → 2,400 N/㎟ |

|

|

Product Use(Applications)

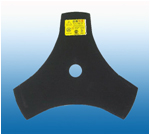

Martempering

| Hand Saws |   |

|---|---|

| Circular Saw Blades |  |

| Band Saws |   |

| Reaper blades |    |

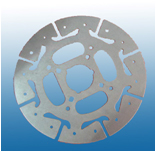

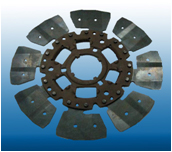

Austempering

| Cusion plate |   |

|---|

Patenting

| Seat belt spring |    |

|---|---|

| High-strength spiral springs |

|

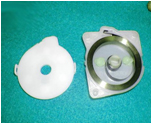

Flapper Valve/Shock Absorbers

- Special hardened and tempered spring steels should provide a high limit of elasticity, high bending strength and high resistance to shocks and fatigue.

- Nastech Special hardened and tempered spring steels are widely used in high quality flapper Valves in compressor and shock absorbers.

Flapper Valve

Reed Suction

Reed Discharge

Shock Absorber

Characteristic

Chemical Composition

| Code | C(%) | Si(%) | Mn(%) | P(%) | S(%) | Cr(%) | Remarks |

|---|---|---|---|---|---|---|---|

| NASTECH 20C | 0.95~1.05 | 0.10~0.35 | 0.25~0.55 | Max 0.030 | Max 0.020 | Max 0.40 | Equivalent Sandvik20C |

Mechanical Properties

| Hardness(Hv) | Tensile Strength(N/mm2) | Roughness(㎛) | Remarks |

|---|---|---|---|

| 500 ~ 670 | 1,700 ~ 2,200 | Ra 0.13(Max) |

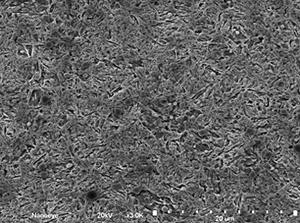

Microstucture

|

Tempered Martensite with fine spheroidized carbide (Average : 0.45 ~ 0.65㎛, Max : 2㎛) |

Size Available